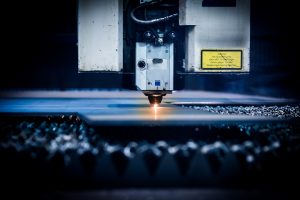

Steam turbines are a major energy generation source for many machine types and industries globally. This combustion engine is effective in producing high levels of electric power for big scale and small scale power-driven elements. Prevalent for years, steam turbines convert pressurized steam into thermal energy for power rotating output shaft operation.

Globally, multiple regions operate steam turbines; it contributes to 88% of overall energy generation in the United States. Generally, resources like coal, gas, solar energy, and nuclear energy heat the water and that produces steam. The types of machines that use steam turbine power for electricity include missiles, airplanes, or ship propulsion, and power generators. Statistically, the expected CAGR of the steam turbine industry is 1.18% within the forecast period of 2020-2027.

In this article, you would learn about the main steam turbine components that are responsible for steam-based power generation.

What is the need for identifying the steam turbine components?

The parts that make up the steam turbines contribute to the overall output and determine their capacities. Thus, if you are operating or developing a steam turbine, knowing what the components are is important for easier management. Also, operators can properly conduct maintenance activities and optimize turbine performance if they know which parts to focus on.

Notably, these steam turbine components are common elements for most steam turbine models. But, the placement and application of the parts can differ depending on the type of steam turbine. They do perform particular fundamental tasks regardless of their arrangement. So, understanding each component well is necessary.

Basic guide to major steam turbine components

Essentially, the parts of the steam turbine can fall under particular categories. All of them individually play an important role in the operation of the turbine and the production of kinetic energy and electricity. The following are the main types available.

- Rotors

The rotors mainly constitute the risk assembly and shaft portions of the bucket. Typically, the shaft component expands through the bearing cases in most models. It is important to note that both ends of the shaft are connected to specific components. Indeed, one edge of the shaft connects to the driven pump. On the other hand, the second shaft ending works with the over-speed trim system and the speed governors.

- Steam chest/casing

It is important to note that this particular component of the steam turbine connects two important lines. The steam chest connects to the high-pressure steam supply line, and the casing joins the low-pressure steam exhaust line.

- Labyrinth seal

A labyrinth seal is a part of a steam turbine that acts as a winding path for leakage prevention. This mechanical seal is typically available in the bearings of the axle. Generally, it reduces the lubricating oil leakage from axle bearing.

In steam turbines, this component only allows a little leakage to release from the high pressure or low-pressure sides. Not to mention, manufacturers keep very little clearance between shaft and labyrinth.

- Governor system

This is a type of control system that is sensitive to speed. In steam turbines, governor valve placement controls the steam flow and consequently the turbine speed. The Governor system includes a steam valve, rotating weights opposed to springs, and an interconnecting linkage.

Ordinarily, in steam turbines, any speed changes cause governor weights to re-position, along with the governor valve. Pump power requirements and changes in turbine exhaust-steam and in-let conditions cause such speed changes.

- Casing sealing glands

In steam turbines, the present turbine gland sealing system (TGSS) ensures that no steam escapes from casing and shaft penetrations. Also, it makes sure that air does not leak into turbine glands that have low pressure. Usually, segmental carbon springs with spring backing are used here. Plus, there is a spring-backed labyrinth portion that supplements the higher exhaust steam-centric glands.

- Sentinel valve

This component exists on the turbine casing at the top portion of the exhaust end. Essentially, the sentinel valve works as a warning device for huge turbine exhaust end casing pressure. Indeed, when the pressure crosses over the regular operating pressure, a little bit of steam visibly gets out of this valve. Also, it emits a slight sound as well.

- Nozzle ring

The nozzle ring is present in steam turbines, mainly at the inside bottom region of the steam end casing. There are nozzles inside of this ring; these nozzles help give the steam flow the right direction to the first row blades of the Curtis stage.

- Reversing blade assembly

This is present in the middle of the two-layered Curtis stage blade rows and is typically fixed with the nozzle ring. In a steam turbine, the reversing blades help turn the steam flow back when it gets out of the first blade rows. Then, it commands the steam flow direction towards the second blade rows (Curtis stage). Besides, the position of the reversing blade assembly is close to the spacers.

Conclusion

Overall, there are multiple components of steam turbines that individually and together ensure steady operation of the system. It is important to know about each of their contributions to the steam turbine performance for suitable assembly and maintenance.